How to Calculate Predetermined Overhead Rate: Formula & Uses

This predetermined overhead rate formula can be best estimated by obtaining a break-up of the last year’s actual cost and incorporating seasonal effects of the current period. Again, that means this business will incur $8 of overhead costs for every hour of activity. That means this business will incur $10 of overhead costs for every hour of activity. Companies need to make certain the sales price is higher than the prime costs and the overhead costs. In some industries, the company has no control over the costs it must pay, like tire disposal fees. To ensure that the company is profitable, an additional cost is added and the price is modified as necessary.

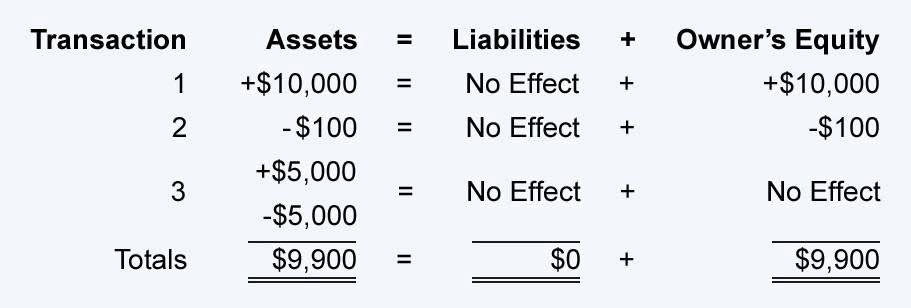

Calculation of Predetermined Overhead and Total Cost under Traditional Allocation

In addition to this, project planning can also be done with the use of an overhead rate. It’s because it’s an estimated rate and can be predicted at the start of the project. Businesses normally face fluctuation in product demand due to seasonal variations. Fixed overheads are expected to increase/decrease per unit in line with the seasonal variations. So, the cost of a product in one period may not reflect the cost in another period—for instance, the cost of freezing fish increases in the summer and lowers in the winter. The business is labor-intensive, and the total hours for the period are estimated to be 10,000.

- The estimate is made at the beginning of an accounting period, before the commencement of any projects or specific jobs for which the rate is needed.

- A company that excels at monitoring and improving its overhead rate can improve its bottom line or profitability.

- Remember that product costs consist of direct materials, direct labor, and manufacturing overhead.

- For instance, in a labor-intensive environment, labor hours were used to absorb overheads.

- It’s a simple step where budgeted/estimated cost is divided with the level of activity calculated in the third stage.

- The expected overhead is estimated, and an allocation system is determined.

Predetermined Overhead Rate Calculation (Step by Step)

Remember that product costs consist of direct materials, direct labor, and manufacturing overhead. A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs. Once a company has determined the overhead, it must establish how to allocate the cost. This allocation can come in the form of the traditional overhead allocation method or activity-based costing.. A predetermined overhead rate is calculated at the start of the accounting period by dividing the estimated manufacturing overhead by the estimated activity base.

Estimate budgeted overheads

Based on the manufacturing process, it is also easy to determine the direct labor cost. But determining the exact overhead costs is not easy, as the cost of electricity needed to dry, crush, and roast the nuts changes depending on the moisture content of the nuts upon arrival. However, the problem with absorption/traditional how is sales tax calculated costing is that we have to ignore individual absorption bases and absorb all overheads using a single level of activity. Hence, this is a compromise on the accuracy of the overall allocation process. On the other hand, the ABC system is more complex and requires extensive administrative work. If the business used the traditional costing/absorption costing system, the total overheads amounting to $26,000 will be absorbed using labor hours.

What information do you need to calculate predetermined overhead rate?

Direct costs are costs directly tied to a product or service that a company produces. Direct costs include direct labor, direct materials, manufacturing supplies, and wages tied to production. Small companies tend to use activity-based costing, whereas in larger companies, each department in which different processes of production take place typically computes its own predetermined overhead rate. The formula for the predetermined overhead rate is purely based on estimates. Hence, the overhead incurred in the actual production process will differ from this estimate. The predetermined overhead rate, also known as the plant-wide overhead rate, is used to estimate future manufacturing costs.